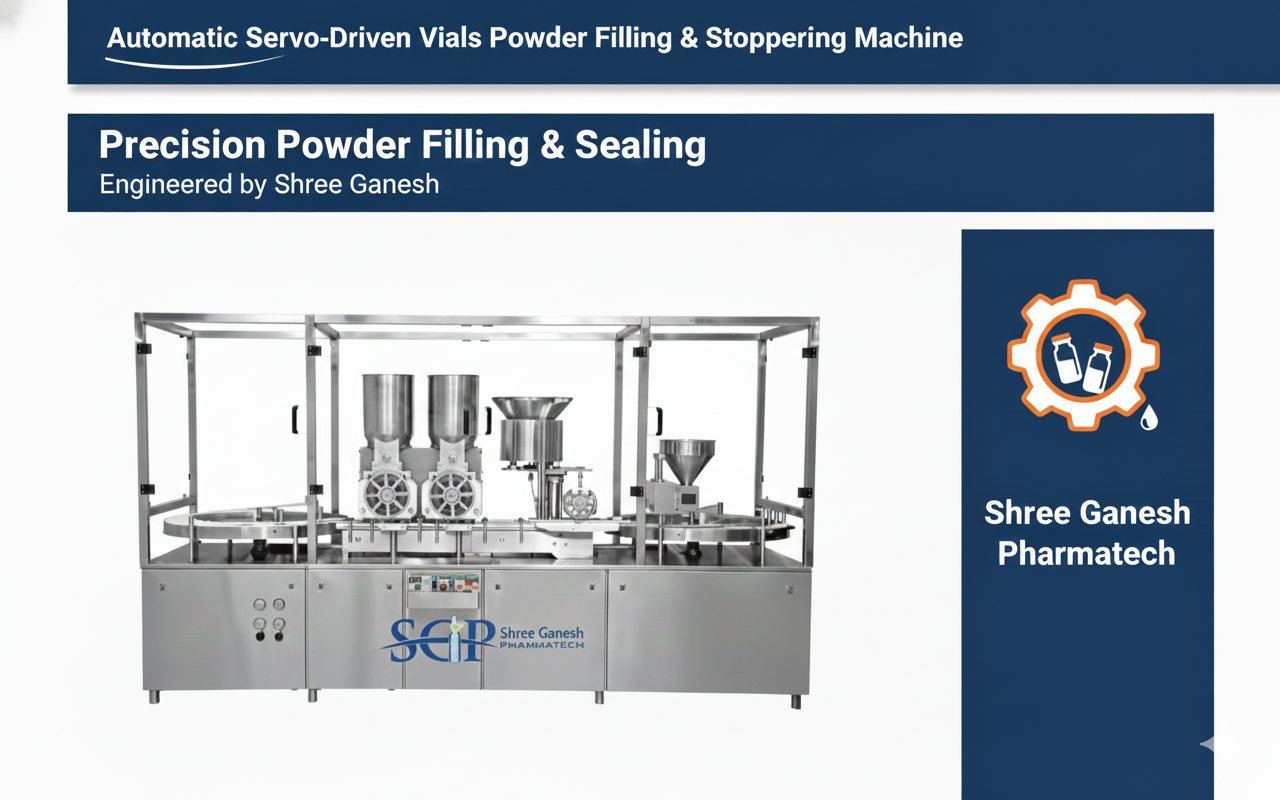

Product Description

The SGP-VPF Series is a high-performance, fully automatic system designed for the precise dosing of dry powder into glass vials, followed by immediate rubber stoppering.

This machine utilizes an advanced Auger-based Servo Filling mechanism, ensuring that even the most delicate pharmaceutical powders are handled with extreme accuracy. The integrated stoppering unit ensures a sterile seal, making it an ideal solution for injectable antibiotic powders and other dry-fill pharmaceutical applications.

Technical Specifications

| Feature | Details |

| Model | SGP-PF-SERVO (High Speed) |

| Filling System | Precision Auger Filler (Servo Driven) |

| Filling Range | 50mg to 50 grams (With appropriate auger tools) |

| Output Speed | 60 to 120 Vials per minute (Depending on powder & volume) |

| Accuracy | $\pm 1\%$ to $2\%$ (Depending on powder consistency) |

| Stoppering Type | Vacuum-suction based Pick & Place system |

| Vial Sizes | 2ml to 100ml (Glass or Plastic) |

| Material of Construction | Contact: SS 316L |

| Control System | Siemens/Delta PLC with 7″ Color Touchscreen HMI |

Advanced Safety Features

To ensure operator safety and product integrity, the machine is equipped with:

Safety Cabinet Interlock: The machine automatically stops if the toughened glass safety doors are opened during operation.

Emergency Stop: Strategically placed “E-Stop” buttons for immediate shutdown.

No Vial – No Fill – No Stopper: Integrated infrared sensors ensure that powder is only dispensed if a vial is present, and a stopper is only placed if a filled vial is detected.

Overload Protection: The motor and servo drives are equipped with overload sensors to prevent mechanical damage.

Low Air Pressure Alarm: Visual and audible alarms if the pneumatic pressure drops below the safe operating limit ($< 6$ Bar).

Salient Features (Key Highlights)

Servo Control: Independent servo motors for the auger filler provide micro-adjustments for weight without stopping the machine.

Vacuum Stoppering: High-efficiency vacuum system for picking and placing rubber stoppers accurately.

cGMP Design: All contact parts are easily removable for autoclaving/sterilization. No “dead corners” to prevent powder accumulation.

Dust Extraction: Built-in dust collection nozzles at the filling point to keep the environment clean.