Shree Ganesh Pharmatech’s powder filling line centers around a robust, stainless steel auger filler that delivers precise dosing with strong safeguards. It’s easily expandable into a full automated line covering powder fill → checkweigher → capping → labeling → coding → packaging. The systems are cGMP-ready, safe, and flexible, ideal for filling powders from lab to production scales.

Shree Ganesh Pharmatech range of pharmaceutical equipment, including Vial Washing Machines, Bottle Washing Machines and Vial Bottle Filling Lines, shows their commitment to providing comprehensive solutions for pharmaceutical production and packaging. Their focus on quality, leadership, engineering excellence, and technology is evident in their products.

Shree Ganesh Pharmatech’s commitment to utilizing the latest technology and maintaining a high standard of workforce excellence has clearly resulted in the development of high-quality pharmaceutical equipment. Their focus on Vacuum Cleaning Machines, Rotary Bottle Washing Machines, and Powder Filling Machines demonstrates their versatility and ability to cater to various industries.

Shree Ganesh Pharmatech’s focus on quality improvement and innovative technology aligns perfectly with their goal of providing outstanding products. Their commitment to customer service and building long-term relationships with clients, both domestically and internationally

Shree Ganesh Pharmatech’s team of highly qualified engineers is dedicated to exceeding customer expectations by providing expert guidance, engineering excellence, and employing the most modern techniques. Their professional approach ensures that customers receive the best possible service and solutions.

Pharmaceutical machinery encompasses a wide range of equipment used in the pharmaceutical industry for various purposes, including manufacturing, processing, packaging, and labeling of pharmaceutical products. Some common types of pharmaceutical machines included.

Liquid Filling Machine: Used to fill bottles, vials, or ampoules with liquid medication.

Powder Filling Machine: Used to fill containers with powdered medication.

Labeling Machine: Used to apply labels to pharmaceutical products.

Capping Machine: Used to cap bottles or vials containing pharmaceutical products.

Bottle Washing Machine: Used to clean bottles before filling them with pharmaceutical products.

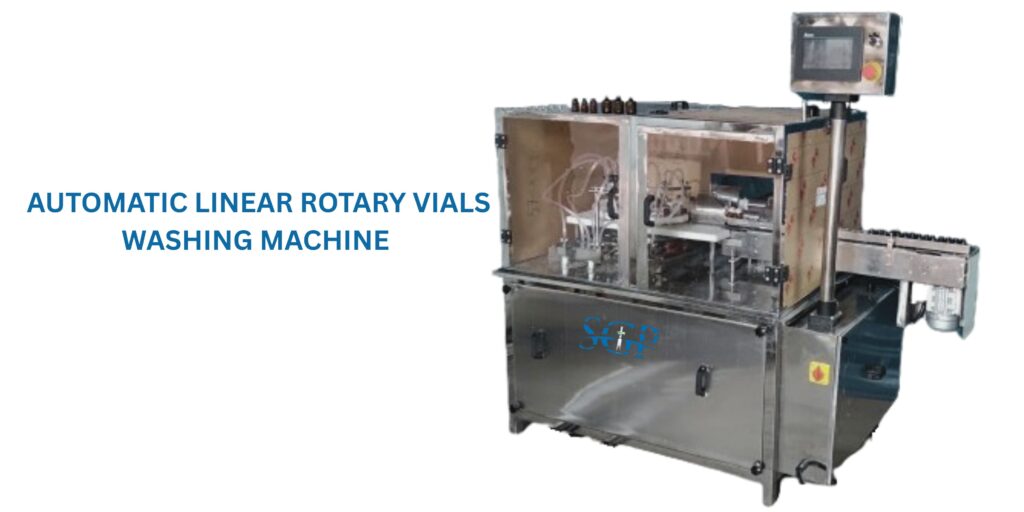

Vial Washing Machine: Used to clean vials before filling them with pharmaceutical products.

Syringe Filling and Sealing Machine: Used to fill and seal syringes with liquid medication.

Bottle Liquid Syrup Filling Line

A bottle liquid syrup filling line typically consists of several machines working together to automate the process of filling bottles with liquid syrup. Here are the key machines commonly found in such a line:

Bottle Unscrambler: This machine orients and feeds empty bottles onto the filling line conveyor.

Bottle Washing Machine: Cleans and sanitizes the bottles before filling.

Liquid Filling Machine: Fills the bottles with liquid syrup to the desired level. This can be a piston filler, gravity filler, or other types depending on the viscosity of the syrup.

Capping Machine: Applies caps or closures to the filled bottles.

Labeling Machine: Applies labels to the bottles.

Induction Sealer: Seals the caps onto the bottles using induction heating.

Checkweigher: Weighs the filled bottles to ensure they have the correct amount of liquid.

Bottle Drying Machine: Dries the bottles after washing.

Coding and Marking Machine: Prints batch numbers, expiry dates, or other information on the bottles.

Packaging Machine: Packs the filled and sealed bottles into boxes or cartons for distribution.

These machines can be integrated into a single automated line, with each machine feeding into the next to streamline the production process.

Vial Powder Filling Line

A vial powder filling line is designed to automate the process of filling vials with powdered substances. Here are the key machines typically found in such a line:

Vial Washing Machine: Cleans and sanitizes the vials before filling.

Vial Filling Machine: Fills the vials with powdered substance to the desired level. This can be done using a variety of filling techniques, such as auger filling or vacuum filling, depending on the characteristics of the powder.

Vial Sealing Machine: Seals the filled vials with caps or stoppers.

Vial Labeling Machine: Applies labels to the filled and sealed vials.

Induction Sealer: Seals the caps or stoppers onto the vials using induction heating.

Checkweigher: Weighs the filled vials to ensure they have the correct amount of powder.

Coding and Marking Machine: Prints batch numbers, expiry dates, or other information on the vials.

Vial Capping Machine: Applies caps or stoppers to the filled vials.

Vial Inspection Machine: Inspects the filled vials for any defects or contaminants.

Packaging Machine: Packs the filled and sealed vials into boxes or cartons for distribution. These machines can be integrated into a single automated line, with each machine feeding into the next to streamline the production process.

For an Injectable Ampoule Line, you’ll typically need a series of machines to handle various stages of production. Here’s an outline of the machines commonly used in such a line:

Ampoule Washing Machine: This machine cleans the ampoules before filling. It may use different washing methods such as ultrasonic cleaning, hot air drying, and sterile air washing.

Ampoule Sterilization Tunnel: After washing, the ampoules pass through a sterilization tunnel to ensure they are sterile before filling.

Ampoule Filling and Sealing Machine: This machine fills the ampoules with the liquid medicine and then seals them. It ensures accurate filling and sealing to maintain the integrity of the product.

Ampoule Inspection Machine: This machine checks the filled and sealed ampoules for any defects such as cracks, leaks, or improper seals.

Ampoule Labeling Machine: After inspection, the ampoules are labeled with necessary information such as product details, dosage, and expiry date.

Ampoule Packing Machine: Finally, the labeled ampoules are packed into boxes or other packaging materials for distribution.

==================================================================================================

Pharmaceutical machines are designed with several key features to ensure efficiency, compliance, and safety in pharmaceutical production. Some significant features include:

Compliance: Pharma machines are designed to meet regulatory standards such as cGMP (current Good Manufacturing Practice) to ensure product quality and safety.

Hygiene: Machines are constructed using materials that are easy to clean and sanitize to prevent contamination.

Accuracy: Machines are designed to deliver precise measurements and dosages to ensure the consistency and efficacy of pharmaceutical products.

Automation: Many pharmaceutical machines are fully automated to improve efficiency and reduce the risk of human error.

Flexibility: Machines are often designed to be versatile and able to handle different types of products and packaging formats.

Safety: Machines incorporate safety features such as interlocks and guards to protect operators and ensure safe operation.

Ease of Maintenance: Machines are designed for easy maintenance and servicing to minimize downtime and ensure continuous operation.

Data Logging: Some machines feature data logging capabilities to track production parameters and ensure traceability.

Energy Efficiency: Modern pharmaceutical machines are designed to be energy-efficient to reduce operating costs and environmental impact.

User-Friendly Interface: Machines are equipped with user-friendly interfaces for easy operation and monitoring of production processes.

=================================================================================================