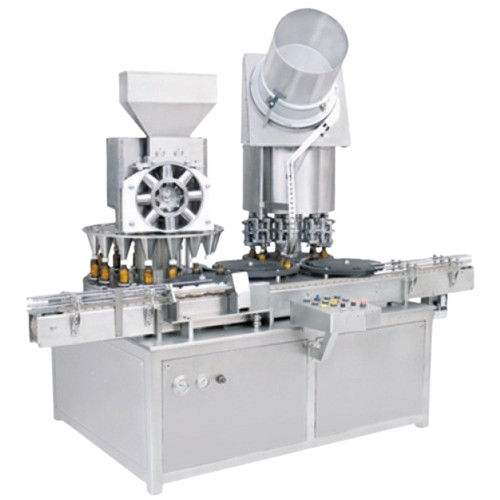

Principle: The machine operates on the vacuum principle with a rotary star wheel, piston assembly, and a rotary funnel head.

Structure: It is self-supported on stainless steel structures and enclosed in a stainless steel body with an elegant matt finish.

Components:

- Conveyor: Carries containers at the desired speed.

- Rotary Star Wheel: With 16 station funnels for filling.

- Powder Filling Head & Piston: For accurate filling.

- Rotary Capping Head: For sealing.

- Cap-feeding Bowl: For delivering caps to bottles.

- Containers are fed from an air jet cleaning machine or unscrambler onto an SS Slat conveyor.

- The containers move below the funnels through a feed worm and in-let star wheel with 16 station funnels.

- The powder filling head, mounted from the center pipe, allows for adjusting the position of the wheel and setting the weight by adjusting the piston working.

- Powder is filled in the hopper, and the agitator in the hopper fills the powder in the rotary filling head consistently and uniformly.

- The powder wheel consists of a piston in each feeding head and a vacuum plate behind the powder wheel, which fills the powder in the head by suction of vacuum, and the fill weight can be adjusted by piston working.

- After filling, the powder head indexes further, and there is a closed powder scrapper to remove excess powder.

- The vacuum remains in the head until the filled head reaches a vertical position to drop powder into the funnel by using compressed air, sterilized low-pressure air, or nitrogen gas to flush the powder out of the port of the powder wheel and fill it into the funnel.

- Funnels are mounted on a rotary plate aligned with bottle mouths and move on a star wheel assembly with an up and down platform to tightly fit and connect with the funnel for filling.

- After filling, the star wheel brings the bottles below the sealing head, where the sealing head performs the operation of threading and sealing the bottles.

- The containers then move for further processing, such as inspection, labeling, or packing.

TECHNICAL SPECIFICATION :

Here are the technical specifications for the SGP-100 powder filler and sealer machine:

- Model: SGP – 100

- Direction: Left to Right

- Output Capacity: Up to 100 bottles/min for 15 to 20 grams filling (depends on powder properties & operating atmosphere)

- Filling Capacity: 5 grams to 50 grams (single dose, with change parts)

- Accuracy: ±1% To ±3% (depends on consistency and uniformity of bulk density of powder under controlled humidity)

- Height of Conveyor: Adjustable from 900 to 950 mm

- Electrical Motor:

- Main Machine: 3 HP / 2.25 kW

- Orientation Bowl: 0.25 HP / 0.18 kW

- Conveyor: 0.75 HP / 0.56 kW

- Auger Screw Motor: 0.25 HP / 0.18 kW

- Vacuum Pump: 1 HP / 0.75 kW

- Dust Collector: 1.5 HP / 1.18 kW

- Electric Power Consumption: 5.12 kW / 3 Phase (voltage & frequency as per customer site)

- Dimensions: 2550 mm (L) x 1225 mm (W) x 2200 mm (H)

- Net Weight: Approx. 1750 kg