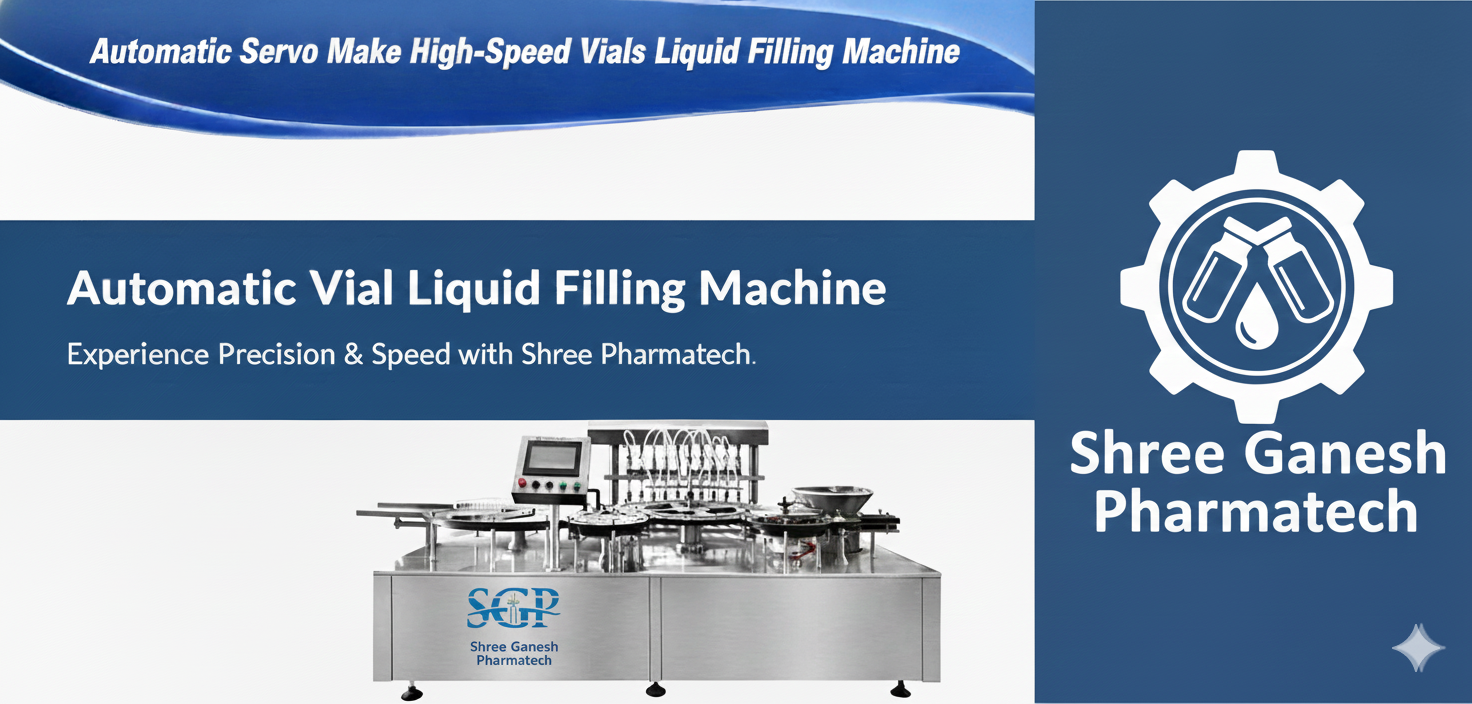

AUTOMATIC SERVO MAKE & NONE SERVO MAKE VIAL LIQUID FILLING MACHINE

Salient Features

Advanced Servo Technology: Uses high-precision servo motors for volumetric piston movement, allowing for instant volume adjustment via the HMI without mechanical changes.

“No Vial – No Fill” System: Integrated sensors prevent liquid wastage by ensuring that nozzles only fire when a vial is detected.

Diving Nozzle Mechanism: Filling nozzles dive deep into the vial and rise during the filling process to prevent foaming and splashing.

cGMP Compliant: The machine features a sleek, crevice-free design and stainless steel finish to meet international pharmaceutical standards.

Safety Enclosure: Equipped with a toughened glass cabinet to protect the product from contamination and ensure operator safety.

Utility Requirements

Electrical: 415V AC, 3 Phase, 50 Hz.

Pneumatic: Clean, dry compressed air at 6 Bar pressure.

Marketing Content for Your Banner:

Headline: High-Speed Servo Controlled Vial Filling Solutions

Sub-headline: Engineering Excellence by Shree Ganesh Pharmatech

Key Highlights: * $\pm$ 0.5% Filling Accuracy

Touchscreen Volume Control

Zero-Contamination Design

Technical Parameters

| Feature | Specification |

| Model | SGP-SERVO-VFM |

| Filling Range | 2ml to 100ml (with interchangeable pistons) |

| Filling Accuracy | Within $\pm$ 0.5% (Servo Controlled) |

| Number of Heads | 4 / 6 / 8 / 12 Filling Heads |

| Output Speed | 60 to 240 Vials per minute (depending on volume) |

| Control System | PLC based with High-Resolution HMI Touchscreen |

| Drive Mechanism | High-Precision Servo Motors |

📍 Address:

4, Devashray Ind. Estate,

Opp. Radhe Residency,

S.P. Vatva Ring Road,

Vatva, Ahmedabad – 382445,

Gujarat, India

📞 Mobile: +91 98250 18210

📧 Email: shreeganeshpharmatech@gmail.com

🌐 Website: pharmaceuticalsmachines.com